Weixian Unit 79 Introduction and Different Neutralization System Comparison

Jul 06, 2023

1. Description Of Weixian’s Unit 79

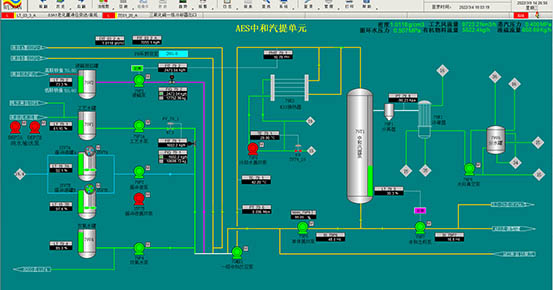

1.1 The principle of WEIXIAN’s Unit 79 Neutralization and Dioxane Stripping is that acid and base raw materials alone with 10 times (1000%) cooled, degassed and dioxane stripped SLES to mix and react in the Neutralization Reactor (79MX1). In the reaction, a small quantity of heat is generated which causes a very sight temperature rise (3-5℃). That makes sure the pH value of neutralizing materials is stable and color is light. Meanwhile, the Neutralization Reactor (79MX1) keeps outlet pressure constantly at 0.3 bar, makes the feeding of acid, base, buffer and bleaching agent stable.

1.2 The material that exit from Neutralization Reactor (79MX1) enters the Stripping Tower (79T1). Under vacuum and low temperature condition (45-55℃), the material is evaporating moisture, cooling down, removing dioxane and degassing. Because there is no rotating equipment, and material doesn’t contact with the inner wall of Stripping Tower; maintenance, electric power and cleaning is not required. Also, the duration that material pass from Neutralization Reactor to Stripping Tower is enough for bleaching.

1.3 At the bottom of Stripping Tower (79T1), the material’s (has been cooled, degassed and dioxane stripped) quantity is 10 times of capacity, through 79P6 SLES Recycling pump, goes to Neutralization Reactor (79MX1). So that 79MX1-79T1-79P6 forms the main process line of Unit 79.

1.4 The material (has been cooled, degassed and dioxane stripped) goes through SLES Transferring Pump (79P7) and get discharged from the system. Low temperature steam is condensated by condenser, and the condensated water (contains dioxane) is discharged (200ppm, 75kg/t SLES). The Recycling Vacuum Pump (79P9) creates the vacuum condition.

1.5 Subsidiary materials feeding: the pure water is controlled by a mass flow meter and a adjusting valve (the small adjusting valve is for producing high-concentration product, big adjusting valve is for low-concentration product). The liquid caustic soda is also controlled by a mass flow meter and adjusting valve; buffer and bleaching agents are controlled by metering pumps.

1.6 This system also produces AOS by adopting the bypass of Neutralization Reactor (79MX1) outlet. While producing AOS, Vacuum Pump doesn’t work, the neutralized material doesn’t need to get cooled down, it goes to sultone hydrolysis by Material Pump 79P7.

1.7 The system is under vacuum condition and pH value ≤ 7.5, the temperature rise of neutralization reaction is very less (material temperature ≤ 55℃), and achieves the best producing requirements of SLES ammonium salt.

2. Different SLES Neutralization Technology Comparison

At present, there are four different continuous neutralization technologies exist: 1. Double-step Neutralization of Italian technology; 2. Pump Type Neutralization of American technology ; 3.Vacuum Neutralization of Italian technology and 4. Neutralization and Dioxane Stripping of WEIXIAN.

The former two types are common neutralization technologies, both are using a high-speed shearing mixing equipment to mix the feeding and re-fluent SLES fully, then through a SLES recycle pump and a cooler to remove heat of neutralization. After that, 15 times (1500%) of yield back to neutralization mixing equipment to re-flux, 1 time of yield to product handling. The difference between these two types is: pump type neutralization goes to product handling directly. However, double-step neutralization first go to 2nd mixing equipment to remix, then to product handling. The advantage of these two types is both have a mass flow of SLES re-flux, make the temperature rise lower than 5℃ and pH value stable. According to practical experiences, as long as the SO3 concentration, free oil content and especially the sulphate staying time keep the same, the various indicators will be all the same, such as pH stability and dioxane content.

The latter two types are both multi-function neutralization technologies, integrating neutralization mixing, neutralization cooling, vacuum dioxane stripping and vacuum degassing.

The vacuum neutralization transfers the reaction materials to wiped-film evaporator in which reaction take place. Simultaneously, moisture evaporating, dioxane removing and degassing are conducting under vacuum condition. This technology adopts one wiped-film evaporator for neutralization mixing and moisture evaporation, and the wiped-film evaporator has a limited evaporation area. It is featured in high cost and high motor power consumption and the feeding quantity of SLES is limited. Generally, for a 3.8t/h SLES plant, the valid evaporation area is 10㎡ (without SLES re-flux). If it has 2-3 times re-flux, the valid evaporation area need to achieve 30㎡. Regarding this type of equipment, not only the processing consideration, but also cost and power consumption should be big problems. The vacuum neutralization doesn't has SLES reflux, it will cause too much temperature rise, the material temperature would be more than 85℃ and lead to pH value unstable.

The technology of WEIXIAN’s neutralization and dioxane stripping is mixing reaction material in neutralization reaction pump or mixer fully with 10 times (1000%) SLES re-flux, the temperature rise is controlled at about 3-5℃. Then SLES goes to stripping tower and disperse in it. Simultaneously, evaporate the moisture and degas under -0.09/-0.095 mpa vacuum condition. It achieves neutralizing, cooling, dioxane stripping and degassing at same time, and it overcomes the high temperature rise, poor pH stability and high power consumption of the vacuum neutralization technology. Furthermore, it produces SLES with low dioxane content (guaranteed lower than 10ppm, 1-5ppm is achievable) under higher SO3 concentration (3%) and lower free oil content (1.2%), which means low power consumption, low raw material unit consumption and low dioxane content. WEIXIAN’s neutralization and dioxane stripping technology can be also used for neutralize AOS and SLS.

Regarding common neutralization technology, if the dioxane content achieves below 15ppm, the SO3 concentration would be at 2.3-2.5% and free oil content would be at 1.5-1.7%, which means 15 kWh more power consumption and 3-5 kg more organic raw material consumption for producing every ton of 70% SLES.

3. The advantage of Unit 79 summary

First, in regards of SLES neutralizing, cooling, dioxane stripping and degassing, all the parameters of WEIXIAN’s Unit 79 Neutralization and dioxane stripping is better than Ballestra’s Vacuum Neutralization. Second, with Unit 79, the SO3 content can be raised from 2.75% to 3.75% while sulphnation plant producing SLES, and dioxane and free oil content remaining low value. That means the capacity can be increased max 40%, electric power unit consumption can be decreased 40%, without the need of improving dry air quality.

WEIXIAN’s Unit 79 combines neutralizing, material cooling, degassing and dioxane stripping into one process; produces low/high concentrate sodium/ammonium salt of SLES/SLS, and AOS. Its process flow is short and simple, so that operation is stable and easy. 79T1 is static equipment, without motor or rotating parts, it doesn’t brake. Neutralization reaction take place in 79MX1, with large quantity of slurry recycling, rise of temperature is less than 5 ℃, product’s color and pH value is good and stable. It utilizes the heat of neutralization to evaporate moisture and dioxane under vacuum and low-temperature condition, extra heat from heaters is not required. By achieving low dioxane content, low unit electric power consumption, low organic raw material unit consumption and power consumption, it is the best technology among international competitors’.

China Unit 79 Neutralization and Dioxane Stripping, Unit 79 Neutralization and Dioxane Stripping Supplier - njweixian.com